There are two types of underlayment for a metal roof felt paper and synthetic each with its pros and cons.

Woven polypropylene underlayment under metal roofing.

Tri flex xt synthetic roofing is an underlayment material used to provide a waterproofing section between the metal roof and the ceiling underneath.

Shingles for example are just the first line of defense against elemental damages.

10 roof protector underlayment roll best roof underlayment for metal roof.

Underlayment is the final weather barrier between your finished roofing and your roof s raw plywood.

The many style options of metal roofs metal roofing comes in numerous styles that mimic modern architectural shingles unique clay tiles traditional standing seams metal roofs with panels that run vertically up the roof charming wood shakes and more.

Choosing the right roof underlayment.

It is uv resistant the membrane is self sealing where nails have penetrated it for attachment purposes and it is slip resistant.

It s a better and more advanced metal roof underlayment.

11 plastic string reinforced poly sheeting best value roofing underlayment.

The synthetic type is a relatively newer technology and is made by spinning together polyethylene or polypropylene with a polymer.

Make sure the product is designed to be used under metal.

This type of underlayment is critical to a quality roof installation.

12 roofing underlayment wind by mcm best roof underlayment for tile roofs.

13 1 frequently asked questions.

It serves as a moisture barrier as well as a slip sheet.

Once again this is used on cold roof construction.

Features tri flex xt underlayment is made from a high strength woven synthetic material that is coated on both sides with slip resistant polymers.

With the best roofing underlayment you will be able to.

Head to head comparison of our synthetic underlayment vs.

Our synthetic roofing underlayment comes with a 25 year limited warranty.

Synthetic plastic sheet underlayment is less susceptible to wind damage and lies flatter when subjected to wetting after installation.

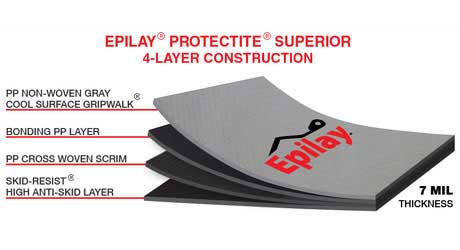

We recommend a polypropylene scrim reinforced underlayment made up of multiple layers.

Synthetic sheet underlayment synthetic plastic sheet underlayment are generally made of polyethylene polyolefin or polypropylene between eight to 30 mils thick.